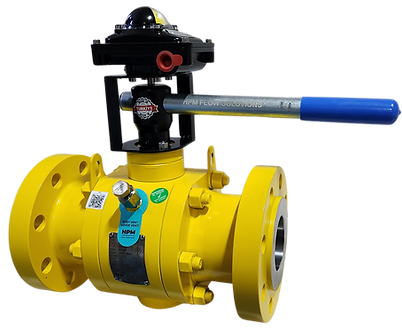

PMSS Ball Valves

DBB

Trunnion

Ball & Seat Rings + TCC 150μm

Flanged Ends ( RF / RTJ )

Butt Welded Ends (BW)

PMSS Ball Valve: Primary Metal Seated and Secondary Soft Seated

The HPM Flow Solutions engineers designed and validated an advanced Primary Metal Secondary Soft Seat (PMSS) for the HPM Flow Solutions ball valves that provides;

• The primary metal seat protects the soft seal and ensures fire safe feature.

• The soft seat ensures bubble tight sealing. The flexible soft sealing in the seating rings is first effective at low pressure ranges.

The selection of the soft material (HNBR 95 Shore A) was accurately made to provide a broad temperature range and extra-long lifecycle.

Informations

Size Range : DN50 to DN600

Pressure : ANSI 150 to ANSI 1500 (PN10 to PN250 / 2.000psi to 10.000psi)

Applicable temperature : -46℃ to +200℃

Connection end : RF / RTJ / BW

Body Design : Side Entry / Top Entry

Bore Type : Full Bore / Reduced Bore

Material : Carbon steel (Forged or Cast), Low temperature steel,

Stainless steel, Duplex / Alloy Steel etc.

-

Wall thickness complies with ASME B16.34.

-

HPM Flow Valves Longer cycle life.

-

HPM Flow Valves can meet NACE specifications for sour gas service when required.

-

Fire Safe tested in accordance with API 6FA / ISO 10497.

-

One-piece ball and stem assures precise positioning

-

Anti blowout / Stem Retention design

-

O-rings plus fire-safe packing prevents leakage

-

Corrosion resistant low friction bearings

-

Anti-static feature between ball, stem and body

-

Emergency seat and stem injection

-

Cryogenic or High Temperature

Valve Operator Options :

-

Hand Lever,

-

Bare Shaft / Stem,

-

Gearbox (Side or Top),

-

Pneumatic actuator,

-

Hydraulic actuator,

-

Gas-over-oil actuator,

-

Hydraulic/electric actuator,

Applicable Standards

Design & Manufacture : API 6D, ISO 14313, ASME B16.34, ISO 17292

Connection Dimension : ASME B16.25, DIN EN 12627, EN 1092-1

Fire Resistance Design : ISO 10497, API 6FA

Inspection & Test : API 6D, ISO 5208, API 598

Material : ISO 15156, API 6D, NACE

Fugitive Emissions: ISO 15848

NACE: MR 01-75 / ISO 15156 compliant

Material Informations

Body : ASTM A105 / LF2 / F304 / F316 / F304L / F316L / F11 / F22 / F51

End Connector: ASTM A105 / LF2 / F304 / F316 / F304L / F316L / F11 / F22 /F51

Ball : ASTM A105+ENP+150μm TCC / LF2+ENP+150μm TCC / 13Cr+150μm TCC / F304+150μm TCC / F316+150μm TCC / F304L+150μm TCC / F316L+150μm TCC / F51+150μm TCC

Seat Rings : ASTM A105+ENP+150μm TCC / LF2+ENP+150μm TCC / 13Cr+150μm TCC / F304+150μm TCC / F316+150μm TCC / F304L+150μm TCC / F316L+150μm TCC / F51+150μm TCC

Stem : ASTM A105+ENP / LF2+ENP / 13Cr-SS 420 / F304 / F316 / F304L / F316L /F51

Seat : H NBR / FKM

O-ring : VITON / NBR

Screw : B7 / B7M / B8M / L7M / B16M

Spring : SS 302 / SS 420 / SS 316 / 17-4PH / 17-7PH / Inconel

Bearing : 304+PTFE / 316+PTFE

Gasket : Flexible graphite+304 / PTFE